The proper functioning of braking systems is fundamental to the safety and control of any vehicle. It’s especially crucial in heavy-duty vehicles like trucks, where the weight and size require extra attention to safety measures. One such innovative and highly effective braking technology is the Jake Brake, an engine braking mechanism widely used in the trucking industry.

Jake Brakes have revolutionized safety measures in large vehicles and brought about a significant shift in how drivers manage speed and control. However, despite their widespread use, the mechanics and benefits of Jake Brakes remain a mystery to many.

In this comprehensive guide, we aim to demystify Jake Brakes, giving you a deeper understanding of their history, how they work, their benefits and applications, and much more. We’ll even address some common misconceptions about Jake Brakes, ensuring you have a rounded understanding of this essential trucking technology. So buckle up and let’s dive into the fascinating world of Jake Brakes.

What Are Jake Brakes?

A Jake Brake is a type of braking system that uses the engine’s power to help slow down a heavy-duty vehicle, like a semi-truck. The mechanism uses the retarding forces within the engine to decrease the speed of the vehicle, reducing the reliance on the traditional wheel braking system.

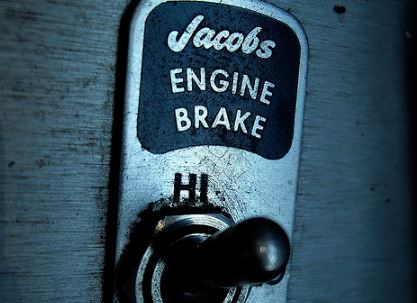

Why is It Called A Jake Brake?

The term “Jake Brake” originates from Jacobs Vehicle Systems, the company that invented this engine braking mechanism. The word “Jake” in Jake Brake is short for “Jacobs.”

How Does A Jake Brake Work?

The working of a Jake Brake involves a process called “engine retarding.” Unlike conventional brakes that utilize the vehicle’s motion and friction to slow down, Jake Brakes use the engine’s own mechanics. When the driver activates the Jake Brake, the exhaust valves in the engine’s cylinders open just after the compression cycle, and some of the compressed air is let out before it can push the piston down.

This means the engine, which usually produces power to drive the vehicle, now works against this power, slowing the vehicle down. The energy used to compress the air is not returned to the engine, which creates a retarding force to slow down the vehicle.

Understanding the difference between Jake Brakes and conventional brakes is also crucial. While conventional brakes rely on friction, which can wear out the brake linings and produce heat that can lead to brake fade, Jake Brakes use the engine’s mechanical power, thus reducing wear on the brake pads and eliminating the risk of brake fade.

By using a Jake Brake, drivers can control their speed more effectively, especially when going downhill, and reduce wear on the conventional brakes, thereby increasing their lifespan and reducing the risk of brake failure. Despite the noise they sometimes produce, Jake Brakes are a boon to the trucking industry, enhancing safety and operational efficiency.

Benefits of Using Jake Brakes

Jake Brakes have garnered widespread acceptance in the trucking industry due to their numerous benefits, particularly in terms of safety and vehicle maintenance. Below, we delve into these advantages in detail.

A. Enhancement of Safety

The primary benefit of Jake Brakes is the enhanced safety they provide. By using engine retarding forces to slow down the vehicle, they offer an additional layer of control beyond the traditional friction-based braking systems. This control is particularly crucial when driving downhill or carrying heavy loads, situations in which high speeds can pose a safety risk. By effectively reducing the vehicle’s speed, Jake Brakes help prevent accidents and maintain safe driving conditions.

B. Reduced Wear and Tear on Regular Brakes

Regular brakes rely on friction to slow down or stop a vehicle, a process that results in wear and tear on the brake linings. Over time, this can lead to a reduction in brake effectiveness and potentially high maintenance costs. Jake Brakes, on the other hand, use the engine’s mechanical power to slow down the vehicle, thereby reducing reliance on the friction brakes and minimizing their wear and tear. This can significantly extend the lifespan of the regular brakes and decrease maintenance costs.

C. Increased Vehicle Control during Downhill Driving

One of the most challenging aspects of driving a heavy-duty vehicle is maintaining control during downhill drives, especially with a heavy load. Jake Brakes come in exceptionally handy in such scenarios. They allow drivers to control their speed without over-relying on the conventional brakes, thus preventing brake overheating and fade. This increases not only the safety of the vehicle and its load but also the confidence of the driver.

Jake Brakes vs. Exhaust Brakes vs. Retarder Brakes – Whats The Difference?

Understanding different types of braking systems and their applications can be invaluable, particularly in industries involving heavy-duty vehicles. Here, we compare Jake Brakes with exhaust brakes and retarder brakes, delving into their functionality differences, suitable applications, and costs.

Functionality Differences

Jake Brakes, exhaust brakes, and retarder brakes, while all aimed at slowing down vehicles, work in fundamentally different ways.

As we’ve discussed, Jake Brakes work by altering the engine valve mechanism, releasing compressed air and creating a retarding force to slow down the vehicle.

Exhaust brakes, on the other hand, create back pressure in the exhaust system to slow down the vehicle. They do this by partially blocking the exhaust path, causing the engine to work harder against the pressure, thus reducing speed.

Retarder brakes, commonly used in buses and coaches, use electromagnetic or hydraulic means to create a retarding force. They are designed to be a supplemental braking system and are especially useful for long descents.

Suitable Applications for Each Type

Jake Brakes are predominantly used in large, heavy-duty vehicles like semi-trucks. Their effective use of the engine’s mechanical power makes them ideal for heavy load management and downhill driving.

Exhaust brakes are generally used in medium-duty vehicles like pickup trucks and RVs. They provide additional braking power but may not be as effective as Jake Brakes for heavy-duty applications.

Retarder brakes are most commonly found in buses and coaches. They offer effective braking without overheating, making them particularly useful for long, downhill routes.

Cost and Maintenance Comparison

The cost of these systems and their maintenance varies. Jake Brakes, given their complexity and effectiveness, are typically more expensive than exhaust brakes. They also require a professional for installation and maintenance.

Exhaust brakes, though cheaper, still require professional installation but have relatively low maintenance costs.

Retarder brakes are also on the higher end of the cost spectrum, especially hydraulic versions, and they also need professional maintenance. However, their efficiency and durability can offset their initial cost.

Common Misconceptions About Jake Brakes

Despite the integral role Jake Brakes play in the trucking industry, there are some common misconceptions surrounding their usage. In this section, we address these myths and provide clarity on the facts.

-

Addressing the Myth of Increased Noise

One of the most common misconceptions about Jake Brakes is that they are excessively noisy. While it’s true that the use of a Jake Brake can produce a distinctive sound, it’s not inherently louder than many other vehicle operations. The noise often associated with Jake Brakes comes from improperly maintained or modified systems. Modern trucks equipped with correctly maintained Jake Brakes and proper muffling devices can operate these braking systems with minimal noise impact.

-

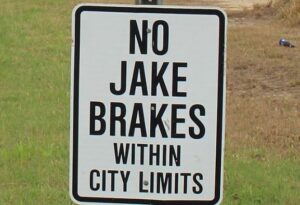

Clarifying Legal Issues and Restrictions

Another misunderstanding revolves around the legality of Jake Brake use. There are indeed places where the use of Jake Brakes is restricted or even prohibited, typically in residential areas or near hospitals. However, these restrictions are due to noise concerns rather than the brake systems themselves being illegal. Importantly, these restrictions are not universal and vary by city, state, or country. Jake Brakes are perfectly legal and widely used in many parts of the world, particularly in areas where heavy-duty vehicles frequently operate.

Jake Brake FAQs

1. Are Jake Brakes only used in trucks?

While Jake Brakes are primarily associated with heavy-duty trucks, they can be used in any diesel-powered vehicle. They are often used in buses and heavy machinery as well.

2. Can you install a Jake Brake on any engine?

Not all engines can accommodate a Jake Brake. The engine must have enough physical space and the right design for a Jake Brake to be installed. Most modern heavy-duty diesel engines are designed to accommodate a Jake Brake, but it’s best to check with a professional or the engine manufacturer.

3. Can using a Jake Brake damage my engine?

No, using a Jake Brake does not damage the engine. In fact, it helps reduce wear and tear on your conventional brakes and can enhance the overall longevity of your vehicle.

4. Do Jake Brakes use more fuel?

Jake Brakes do not consume additional fuel. They utilize the engine’s mechanical power to slow down the vehicle, not extra fuel.

5. Can I use a Jake Brake in all weather conditions?

While Jake Brakes are helpful in many situations, their effectiveness can be impacted by weather and road conditions. For example, on wet or icy roads, Jake Brakes may not provide sufficient braking force. It’s always important to adjust your use of Jake Brakes according to the driving conditions.

[…] injuries, and documenting the physical damage caused. Additionally, reaching out to competent truck accident attorneys is essential as they can facilitate the utilization of this evidence during the investigation process. Such […]

[…] the United States, camper shells are also referred to as a “truck canopy”, “truck cap”, “shell” or “topper”. Use any of those terms, and most p… what you are talking about. Amongst my circle of friends, we pretty much exclusively call them […]

[…] choice between a new or used flatbed tow truck can greatly affect the cost. New trucks come with the latest technology, manufacturer’s warranty, and no wear and tear, but they also carry a higher price. Used trucks, […]